How porcelain stoneware sinks are made?

- January 9, 2024

- 10:57 am

- No Comments

The process of making a porcelain stoneware sink, on the one hand, is relatively simple and at the same time difficult for non-professionals.

To make a truly high-quality product that will serve for many years and will not cause problems, it is advisable to use the “correct” porcelain stoneware, have proven production technology, high-quality equipment and consumables. It makes no sense to discuss the qualifications of a specialist who makes sinks or other porcelain stoneware products, since by default, he must be a high-level professional.

As for the choice of porcelain stoneware for the production of a sink, in theory, it can be made from any porcelain stoneware, but there are nuances that not all customers know about, but which significantly affect the final result both in aesthetic terms and during the subsequent use of the product.

Buying a ready-made porcelain stoneware sink or having it made to order is not all. In addition, you need to install the sink correctly, which, again, as practice has shown, not all specialists who work with traditional plumbing equipment can do. There are precedents for damage to expensive products due to unprofessional installation by third-party contractors.

Therefore, we recommend that you take a serious approach to choosing both the manufacturer of the product and the installer of porcelain stoneware sinks.

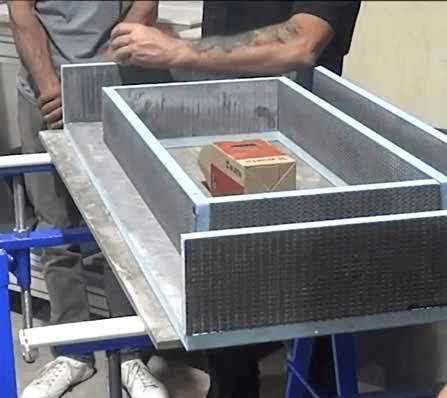

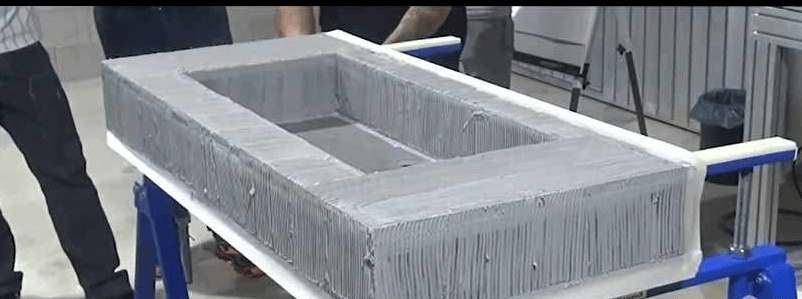

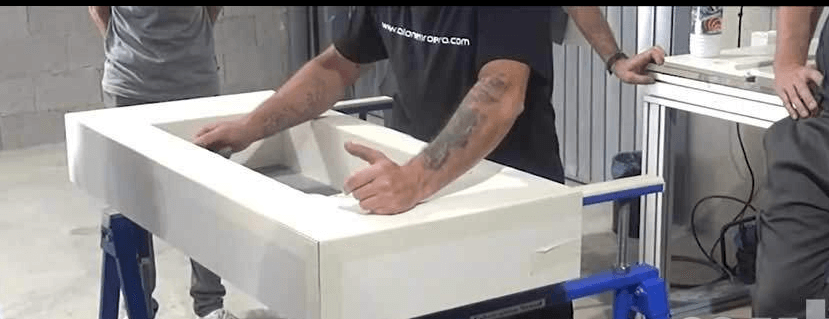

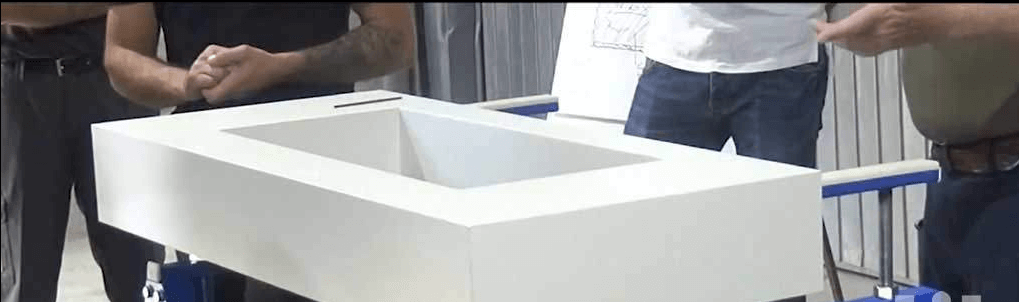

As for the actual design and manufacture of a porcelain stoneware sink, below you can familiarize yourself with the main stages of one of the options for its production.

In short: a detailed design of the product is created, the porcelain tile required in style is selected, a frame is made, waterproofing is done, then pre-cut porcelain tile is installed, seams are formed, a drain is installed, and the product is finished. Next comes packaging, delivery and installation on site.

Tags:

Latest Post

Handcrafted Artistry: How Ceramic Granite Sinks Differ from Mass Production